Mobile Crane Cylinder

— Luffing Cylinder

— Telescopic Cylinder

— Outrigger Cylinder

— Suspension Cylinder

— Outrigger Expansion Cylinder

— Counterweight Cylinder

— Steering Cylinder

Can be customized according to customer requirements.

WHAT WE CAN DO

Can be customized according to customer requirements.

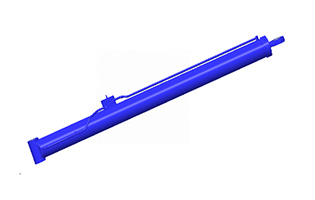

| Luffing Cylinder Features: Realizing the up and down pitching rotation of the boom is the main driving force for lifting Specification: Bore diameter: 100mm~560mm / Rod diameter: 50mm~480mm / Stroke≤5000 mm Pressure: Maximum 36MPa |

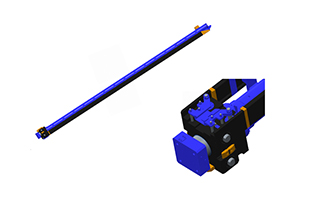

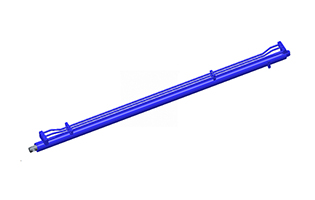

| Telescopic Cylinder Features: Realize the linear telescopic movement of the boom Specification: Bore diameter: 75mm~360mm / Rod diameter: 50mm~320mm / Stroke≤22000mm Pressure: Maximum 42MPa |

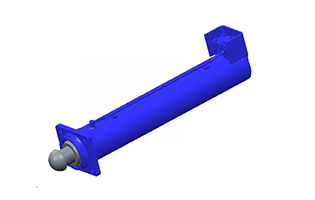

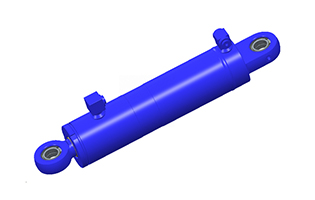

| Outrigger Cylinder Features: Support the weight of the entire equipment when the crane is lifting Specification: Bore diameter: 70mm~360mm / Rod diameter: 45mm~320mm / Stroke≤800mm Pressure: Maximum 42MPa |

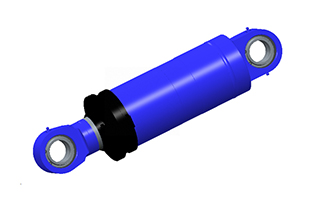

| Suspension Cylinder Features: Damping system for crane chassis Specification: Bore diameter: 85mm~180mm / Rod diameter: 50mm~100mm / Stroke≤300mm Pressure: Maximum 35MPa |

| Outrigger Expansion Cylinder Features: Extend the outrigger cylinder horizontally Specification: Bore diameter: 50mm~75mm / Rod diameter: 25mm~55mm / Stroke≤2500mm Pressure: Maximum 35MPa |

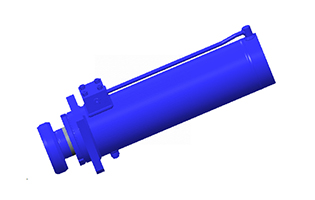

| Counterweight Cylinder Features: For the installation of counterweights Specification: Bore diameter: 85mm~320mm / Rod diameter: 55mm~180mm / Stroke≤1500mm Pressure: Maximum 35MPa |

| Steering Cylinder Features: Steering system for crane chassis tires Specification: Bore diameter: 63mm~200mm / Rod diameter: 36mm~140mm / Stroke≤1000mm Maximum 35MPa |

The compact structure design, the use of high-strength materials, the special heat treatment, and welding processes ensure that the cylinder has a very high fatigue life under high pressure and heavy load.

Provide a variety of surface anti-corrosion treatment solutions: Ni/Cr plating, ceramic spraying, laser cladding, QPQ, etc.

It can be designed and integrated with P.O. check valves, pipe burst safety valve, oil pipes, etc.

The design has a wide range of temperature resistance (-25℃~+120℃), and can provide higher or lower temperature cylinders

The mature cushion design makes the bucket reduce the impact of the cylinder during the excavation operation without reducing

The mature cushion design makes the bucket reduce the impact of the cylinder during the excavation operation without reducing the excavation force and affecting the work efficiency

For the earrings of the integral die forgings, you can choose the standard self-lubricating bushings, and also can be configured according to customer needs