Rotary Drilling Cylinder

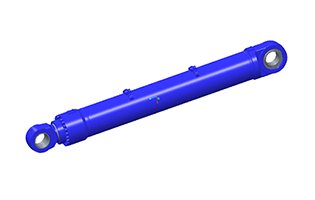

— Luffing Cylinder

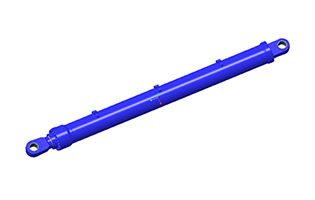

— Mast Cylinder (correcting cylinder)

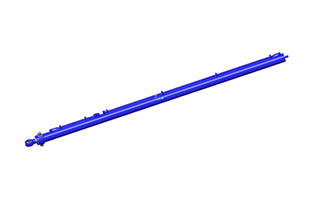

— Pressurized Cylinder

Can be customized according to customer requirements.

WHAT WE CAN DO

Can be customized according to customer requirements.

| Luffing Cylinder Features: Control the luffing angle, adjust the distance between the mast and the host Specification: Bore diameter:125mm~250mm / Rod diameter:90mm~160mm / Stroke≤1640 mm Pressure: up to 32MPa |

| Mast Cylinder Features: Control the mast, adjust the angle of the mast and the ground Specification: Bore diameter:140mm~350mm / Rod diameter:90mm~230mm / Stroke≤5550mm Pressure: up to 32MPa |

| Pressurized Cylinder Features: Control the lifting and lowering of the power head Specification: Bore diameter:125mm~210mm / Rod diameter:90mm~150mm / Stroke≤8500mm Pressure: up to 35MPa |

The compact structure design, the use of high-strength materials, the special heat treatment, and welding processes ensure that the cylinder has a very high fatigue life under high pressure and heavy load.

Provide a variety of surface anti-corrosion treatment solutions: Ni/Cr plating, ceramic spraying, laser cladding, QPQ, etc.

It can be designed and integrated with P.O. check valves, pipe burst safety valve, oil pipes, etc.

The design has a wide range of temperature resistance (-25℃~+120℃), and can provide higher or lower temperature cylinders

The mature cushion design makes the bucket reduce the impact of the cylinder during the excavation operation without reducing

The mature cushion design makes the bucket reduce the impact of the cylinder during the excavation operation without reducing the excavation force and affecting the work efficiency

For the earrings of the integral die forgings, you can choose the standard self-lubricating bushings, and also can be configured according to customer needs