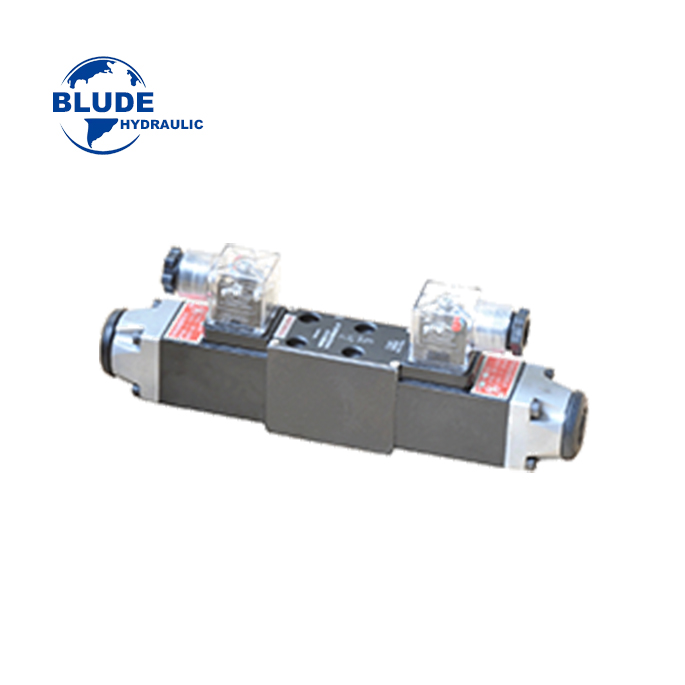

BE Series

Specification: 5/6/10

Rated pressure: 250/350/315 bar

Rated flow: 14/80/120 L/min

Sub-plate mounting, electro magnetic directioanl

WHAT WE CAN DO

Specification: 5/6/10

Rated pressure: 250/350/315 bar

Rated flow: 14/80/120 L/min

Sub-plate mounting, electro magnetic directioanl

BG6-L6X

• Direct solenoid control slide valve

• Installation face follow DIN 24340 A, ISO 4401 and CETOP-RP 121H sub-plate mounting connection sub-plate mounting connection

• Wet-pin AC or DC solenoids with detachable coil

• Replace coil without releasing oil

• Electrical connection as individual or central connection

BG10-L3X

• Direct solenoid control slide valve

• Installation face follow DIN 24340 A, ISO 4401 and CETOP-RP 121H sub-plate mounting connection sub-plate mounting connection

• DC solenoid with removable coil

• Replace coil without releasing oil

BG10-L5X

• Direct solenoid control slide valve

• Installation face follow DIN 24340 A, ISO 4401 and CETOP-RP 121H sub-plate mounting connection sub-plate mounting connection

• DC or AC solenoid with removable coil (using a rectifier to connect to AC)

• Solenoid coil can rotate 90°

• Replacing the coil does not require opening the sealed chamber

• Optional time switch control function

| Specifications | BG6-L6X | BG10-L3X | BG10-L5X | |

| Installation position | Optional | |||

| Ambient temperature range ℃ | -30 to +50 (NBR seals) | |||

| -20 to +50 (FKM seals) | ||||

| Weight | valve kg | / | / | / |

| Sub-Sub-plate mounting kg(G115/01A) | / | / | / | |

| Single solenoid valve kg | 1.5 | Independently wiring:4.3(DC),3.5(AC) | 4.3(DC) | |

| Central monitoring station:4.4(DC),3.6(AC) | ||||

| Double solenoid valve kg | 2.0 | Independently wiring:5.9(DC),4.3(AC) | 5.9(DC) | |

| Central monitoring station:6.0(DC),4.4(AC) | ||||

| Max.operating pressure | Port A,B,P bar | 350 | 315 | 350 |

| Port T bar | 210(DC),160(AC) | 210(DC) | ||

| Max. flow-rate L/min | 80(DC) 60(AC) | 120 | 150 | |

| Flowarea (switching neutral position) | V type mm2 | / | 11(A/B → T);10.3(P → A/B) | / |

| Q type mm2 | for symbol Q 6% of nominal cross section | 2.5(A/B → T) | / | |

| W type mm2 | for symbol W 3% of nominal cross section | 5.5(A/B → T) | / | |

| Fluid | Mineral oil suitable for NBR and FKM seal | Mineral oil (HL, HLP) to DIN 51 524,suitable for NBR and FKM | ||

| Phosphate ester for FKM seal | ||||

| Fluid temperature range℃ | -30 to +80(NBR seal) | |||

| -20 to +80(FKM seal) | ||||

| Viscosity range mm2/s | 2.8 to 500 | |||

| Degree of contamination | Maximum permissible degree of fluid contamination: Class 9. NAS 1638 or 20/18/15, ISO4406 | |||